RESIN RESEARCH RR KWIK KICK EPOXY RESIN FOR SURFBOARDS

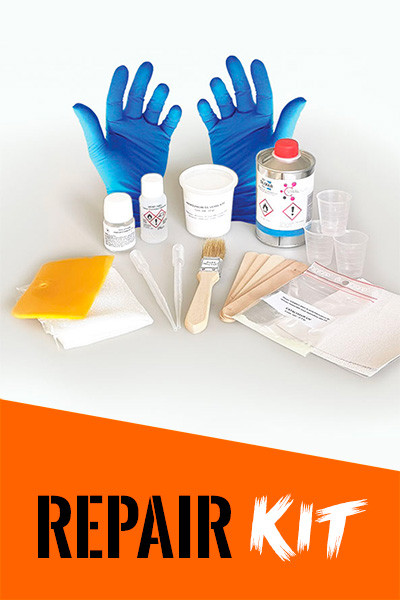

The resin and hardener are designed to be used together and more specifically for the surfboard hot coat. The chemical reaction between the two products is unique and was developed to prevent the resin from leaking from the board (we call this stage B or gel stage). During step B, the epoxy is a gel and can be moved but tends to stay where you put it. This epoxy/hardener mixture has been the system most used by our customers for many years when it comes to making a hot coat.

FEATURES OF RESIN RESEARCH RR KWIK KICK EPOXY RESIN

RR KWIK KICK resin from RESIN RESEARCH is specially designed for the manufacture of surfboards.

Handling

Characteristics

Density

Kg/liter

Viscosity

CPS

Lamination

Impregnation of fiberglass layers

Plugs & inserts

Installation of fin plugs and leashes

Hotcoat

sealing and finishing coat

COMPARATIVE ANALYSIS OF THE MECHANICAL PROPERTIES OF RR KWIK KICK RESIN

Mechanical properties differ between RR 2000, RR Kwik Kick and RR Surf Pro resins.

COMPARATIVE ANALYSIS OF CURING TIMES OF RR KWIK KICK RESIN

Curing times vary depending on resins and their hardeners.

English

English Français

Français Espagnol

Espagnol